Pcakged Unit Substation

Package unit substation normally designed in compact size applied in indoor and outdoor secondary distribution system. There are many types of the packaged unit substation, but the most widely used type is 11kV packaged unit substation because of the voltage grade advantage.

Orecco package unit substation has the advantages of compact size, flexible combination, easy for transportation and installation, no pollution and free maintenance, it is widely used in secondary electrical power distribution system.

Packaged unit substation could be design customized dimensions as required, it is assembled and tested in factory. The package unit substation is the combination of transformer, LV switchgear panel and HV switchgear panel.The inside distribution transformer optional for oil filled type and dry type, so it also named compact transformer substation.

Orecco package unit substation normally installed outdoor because of the protection degree could reach IP66 maximum, so it could work in normal state regardless of any weather changes.

Applications For Packaged Unit Substation

Package Unit Substation Basics: The Definitive Guide

INTRODUCTION

Electricity is not delivered straight from the power station to establishments.

A process is required to reduce the voltage supplied from power stations to a harmless, lower voltage that can be delivered to businesses and homes.

It’s the job of a package unit substation to perform this task.

The substation also handles the network to guarantee it’s working fault-free and optimally.

Do you want to know more about what is package unit substation?

Perhaps you think what it is?

In case you didn’t know yet, a package unit substation is similar to a prefabricated compact substation.

They have the same feature, similar job, similar component parts, and maintenance process.

If you want to know more about this, read further!

CHAPTER 1: Package Unit Substation Definition: What is Package Unit Substation?

Did you know?

Package unit substation is made for:

- indoor switchgear equipment,

- communication and command post,

- modular transformer substation and;

- distributed centers.

Customers needing minimal on-site work and shorter overall delivery times have been the primary driver of package unit substations.

These small distribution substations are subcategorized into container-sized modules.

They can be manufactured, assembled and tested at the factory.

That guarantees simple to transport, quick installation as well as commissioning at site.

Package Unit Substation

Definition of Package Unit Substation

This compact substation is utilized for feeding power from high voltage to low voltage in:

- open cast mines

- metro cities,

- construction sites and more.

The 33kv substation is compact size, which makes it perfect for recurrent shifting.

It is also perfect for outdoor and indoor locations.

The electric distribution is mounted and installed on skin frame, channels or wheels and presented with lifting hooks.

You see:

Package unit substation safeguards the equipment from any environmental influences.

Therefore, it increases transmission substation reliability and availability.

Fences can be removed, that shortens permitting while strengthening the aesthetic look of the package unit substation.

The package unit substation is a cost-efficient and an excellent alternative to more traditional brick and mortar substations.

They have transformed from the first pre-manufactured substations that utilize standard ISO marine containers.

Such marine containers still offer an economical and excellent option for different operations.

However, they do have limitations when it comes to size.

On the other hand, package unit substations are also known as E-houses or electrical substation equipment.

They are constructed based on the particular dimensions of the equipment which will be housed inside them.

The only boundaries come regarding logistics and factors like:

- crane lifting

- transportation and;

- handling facilities

of course, handling capabilities and on-site lifting have to be taken into consideration.

In instances particularly where bigger e-houses are needed, they can be made in modular sections and fastened together once on site.

If we talk about modular units, we are typically referring to an electrical power distribution substation which is collected on a base.

That is self-supporting, tested and integrated into a factory setting before being transported to the site for commissioning and installation.

What’s more:

The compact and customized package unit has a small footprint.

It includes a ready-to-connect primary and secondary cabling along with plug-type contacts.

The applications vary from small distribution systems to the incorporation of renewable generation.

Quick assembly and disassembling also make it simpler to relocate.

That makes it well-suited for use as an auxiliary substation throughout maintenance of repair of current primary substations.

Package Substation Features

Some of the apparent features of using a prefabricated substation are the following:

- safe and easy to operate

- ready to install and compact portable

- designed for better cooling

- perfect for all weather conditions

- superior aesthetics

- customer made design

- low maintenance

- transformer dry type or oil cooled

A package unit substation is one of the most effective, convenient and economical equipment and friendly solutions – safe and simple to operate a substation.

Specifications of Package Unit Substation

Package unit substation are totally self-contained, factory assembled in are enclosed metal cladding.

It has a weatherproof housing capacity prepared for putting into position upon a concrete base pad.

1. High Voltage Compartment

This compartment can be geared with wide selections of high voltage switchgear.

High voltage compartment

For voltages approximately 24kV, average RMU can be presented.

For voltages at least 36kV, insulated switchgear can be presented to safeguard the distribution transformer.

Circuit breaker and load break switches modules can be mixed together in various arrangements as per the needs of the customer.

On the other hand, fused switched option and insulated switch are accessible for voltages at least 36kV.

Switch and fuse switch disconnector can be utilized to various configurations to offer the needed switching, metering and protection needs in the MV side of the substation.

2. Transformer Compartment

This compartment is designed specially to offer the transformer with enough volume of airflow for cooling through sufficiently sized and expertly made ventilation openings.

Transformer Compartment

Such openings situated on both sides of the compartment are designed to stop the sand from reaching the compartment.

The compartment is presented along with a pressure relief system incorporated in the roof or ceiling.

As an alternative, a floor mesh can be given to avoid entry of small animals and other objects.

It also assures constant circulation and air flow.

3. Low Voltage Section

This compartment involves Low Voltage Distribution Board.

It is fed from the secondary part of the transformer.

It can be made in various configurations and arrangements to fit any particular application.

Copper bus bars are given for the neutral and phases suitable to the transformer secondary voltage and existing ratings.

A ground bus connected to the neutral bus is provided as well.

4. Grounding System

The package unit substation creates a total metallic structure bolted together.

Every compartment is presented with grounding busbars.

The LVDB and RMU is presented with ground bus from which connection to the grounding system at the site can be accomplished.

Advantages of Package Substations

If compared to a ground-up construction of a traditional substation, a packaged unit substation provides a host of benefits.

Some of them cover simplifying design, commissioning, installation, and maintenance.

Technology is advanced

One of the fantastic thing about package unit substation is that the technology is advanced, safe and dependable.

Did you know that the shell is made from aluminum zinc plated steel plate?

Its frame also adopts the standard.

You will also find an excellent anti-corrosion for quasi-container materials as well as a manufacturing process.

Its performance guarantees twenty years of no rust.

Plus, the inner seal plate is made from aluminum alloy.

Factory prefabrication

In the design, as long as the designers are required according to the actual substation, the main wiring diagram and the design of the equipment outside the transformer can be made.

Once installed and debugged in the factory, substation construction is indeed realized.

Setting up factories shortens the design and manufacturing cycle, and only needs on-site installation.

Package unit location, a cable connection between the package units, outlet cable connection, and protection.

Calibration, transmission test and other work to be debugged.

It takes about five to eight days for a substation to be installed and put into operation.

That enormously shortens the construction period.

Flexible combination

The 11kv substation is dense because of its compact structure.

It has an independent system, which makes the combination flexible.

On the one hand, we can all use package unit type, that is to say, 33kV and 11kV equipment are installed in all units, and constitute full unit type transformer.

The combination method is especially suitable for the old station transformation in the rural network transformation.

That is, the original 33kV equipment does not move, only one 11kV switch package unit is installed.

There is a fixed combination mode, and the user can use it according to the actual situation.

It can be done by combining some modes to meet the needs of the safe operation.

Investment is fast and effective

Packaged unit substation can lessen:

- construction,

- installation

- commissioning period by an average of 50%.

They can massively lessen costs too.

Imagine if you need to pay for accommodation and travel costs of all the different and costly specialists you’d require to construct a substation directly on the site.

You see:

The substation installation often needs some such specialists to all on the site simultaneously.

That can present massive logistical challenges, particularly if you are in a remote area.

The good thing!

Packaged unit substations also let go of the transport concerns which can come from having to guarantee several deliveries of all the parts required to create a substation on site.

Along with a packaged unit, there’s only one item need to be transported.

Excellent appearance, stress-free to coordinate with the environment.

It is very easy to select the color of the shell of the packaged unit substation.

Package substation in community

In line with the surrounding environment, it is especially suitable for urban construction, such as:

- urban residential areas,

- stations,

- ports,

- airports,

- Parks

Green belts and other densely populated areas can be used as fixed transformers too.

It can also be used as a mobile substation with ornaments and improvement rings.

Quick and easy installation

The idea of packaged unit substation enabled delivery on-site of an overall product pre-connected and tested at the factory.

Only connected to the electrical network remains to be performed.

That enables simplified transport on a container or standard truck.

Streamlined logistics

As an alternative to working with different design and construction employees and numerous product manufacturers, packaged substation provide:

- contemporary, turnkey solution

- single vendor responsible for each aspect of the design, procurement of parts, installation, manufacture, and commissioning.

That denotes that one point of accountability and one point of contact.

That consolidation vastly lessens the difficulty of the project management.

It also reduces the possibility for miscommunication or conflict between vendors.

Lessened footprint

Packaged unit substations are made to take up as less space as possible.

It also meets all the specific needs of a project at the same time.

With this substation, the whole unit fits into one platform.

Therefore, space and transportation requirements are massively simplified.

The units can be lifted and relocated easily if necessary.

It can be customized

Packaged unit substations are made according to international and national standards.

At the same time, it also meets specific customer requirements.

They also need to handle the environmental conditions of the location into account.

Thus, some factors will be considered if you prefer to customize your substation:

- fire detection and suppression systems

- cable entry and exit points

- cooling requirements for high heat rejection equipment

- environmental conditions, like air status and ambient temperature

- thermal insulation needed

- maximum permissible height for transport purposes

- total equipment mass

Such factors and others command how your substation is manufactured.

The design should enable total interconnectivity between every electrical equipment.

That will guarantee that the power cabling and control and achieved easily.

CHAPTER 2: Package Unit Substation Design

Package unit substation is typically designed in compact size applied in outdoor and indoor secondary distribution system.

You will find different types of the packaged unit substation, but the most widely utilized type is 11kV packaged unit substation.

Why?

That’s because of its voltage grade advantage.

Packaged unit substations could be customized design dimensions as needed.

It’s assembled and tested in the factory.

The packaged substation is the combination of:

- transformer

- high voltage switchgear panel

- low voltage switchgear panel

The inside distribution transformer is optional for the dry type of oil filled type.

Apart from being known as a packaged unit substation, it’s also called as compact transformer substation and prefabricated compact substation.

These type of substations are all assembled and tested in the factory.

They are constructed and manufactured to satisfy the specific requirements of the customer.

These substations are utilized for efficient electrical power distribution in medium voltage down to voltage distribution systems.

They are:

- integrating metering & protection

- integrating dry or oil type transformers

integrating SF6 ring main units along with several configurations

Package substation is composite units along with the high voltage switchgear close coupled to the transformer area.

In other cases, the low voltage switchgear is also close-combined to the transformer.

Package units always employ dry-type cast-resin transformers.

Stakeholders and designers must consider package substations.

Why?

That’s because it delivers a cost-efficient solution when it comes to access and requirements for maintenance.

Further, because of the close-combined arrangement, maintenance might take longer.

Thus, it will impact more significant parts of the system.

Care must be taken to guarantee that only High Voltage Authorized Persons have access to the High Voltage equipment.

Package substations might deliver an efficient solution for committed single loads like big chiller stations.

They might also give efficient solutions wherein the distribution strategy has a high resilience like the dual unified work.

Structure of Package Unit Substation

Package unit substation is typically divided into three parts:

- low voltage distribution

- high voltage distribution

- transformer

in a single transportable unit that is ready for operation.

High Voltage Distribution

There are common ways in which an 11kV supply may be delivered to a site:

- by duplicate feeders

- by a ring main

- by a radial feeder

The duplicate supply might be given with either manual or automatic changeover facilities.

HV distribution is interconnection points within the distribution system and power systems.

These are planned and designed comprising:

- high voltage switchgear

- medium voltage switchgear

- major components like transformers and high voltage equipment

- protective equipment and more

the installation supplied global range from standard substation with one busbar to interconnection substations along with various busbar.

High voltage distributions are a crucial component in package unit substation.

The reliability of the substation depends upon it.

Thus, the circuit configuration of the high voltage distribution has to be chosen carefully.

HV is also based on North American practice.

A single phase or three phase high voltage line is taken as close the load as possible and a distribution transformer of appropriate capacity.

Typically, one or more single-phase transformers are set up to feed one or small group of loads, such that the length of the low voltage lines or is removed altogether.

This system is ideally suited to meet the scattered loads of the low load density.

Low Voltage Distribution

Low voltage distribution is based on European practice.

You see:

A three phase transformer of substantial capacity is installed, and low voltage lines are stretched to cater to a set of loads.

This system is best fitted to meet the concentrates loads of high load density.

In European nations, the standard three-phase four-wire distribution voltage level is 230/400 V.

Low voltage distributions, mutually spaced at least 500 to 600 meters, are normally equipped with:

- 1 or 2 1,000 kVA LV transformers

- A three- or four-way switchboard, often made up of outgoing and incoming load break switches making part of a ring main

- 1 or 2 six- or eight-way low voltage three-phase four-wire distribution fuse boards, control and protect outgoing four core distribution cables

Central and North American practice varies fundamentally from that in Europe.

In that, low voltage networks are non-existent practically.

The three-phase supplies to premises in residential regions are very rate.

Transformer

Transformer aims to transfer the power with concentrated efficiency from the generation end to the load end.

The system is chiefly composed of:

- Measuring transformer

- Measuring device at oil temperature and room temperature

Through the automatic and manual control circuit, the safe operation should be set for setting control.

On the other hand, in the European package unit transformer, the oil-immersed transformer can be utilized.

It can also use a dry-type transformer.

However, because of the high cost of the dry-type transformer, the oil-immersed transformer must be preferred in case of no special requirements of users.

That will lessen the manufacturing costs.

The transformer capacity usually is 100 to 1250 kVA.

The maximum should not go beyond 1600 kVA.

CHAPTER 3: Package Unit Substation Components: Different Parts of Package Substation

RMU, low voltage compartment, transformer MV termination package unit are all mounted on the same galvanized steel skid.

Take note:

Low voltage compartments, high voltage compartments, and RMU are presented with factory assembled removable enclosure.

That enclosure mechanically has the organization to be assembled or disassembled at the site by workshop technical through standard tools.

High Voltage Distribution Component Parts

A correct design operated and maintained electrical distribution system is a crucial element in reliability and safety of an electrical system in an industrial plant.

The major components of the HV distribution parts are:

- Live display

- Electromagnetic lock

- High voltage arrester

- High voltage load switch

- High voltage fuse

- High voltage grounding switch

Low Voltage Distribution Component Parts

Low voltage distribution system operates typically at less than 600 volts.

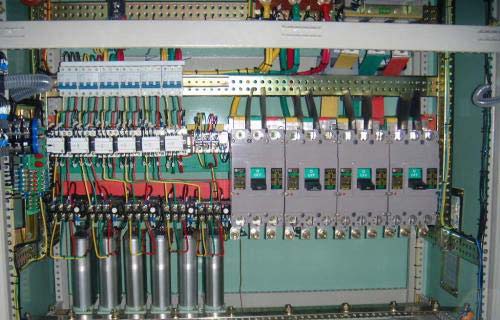

Electrical components inside of LV compartment

A wide array of low voltage power distribution equipment is accessible on the market these days to meet the different needs of:

- Homes,

- Industrial facilities and;

- Commercial buildings

The component part of low voltage distribution system includes:

- Load isolating switch

Load isolating switches are utilized to isolate equipment for the maintenance.

It’s also isolated for transfer of load from one bus to another bus.

The layout of the package unit substation varies on the type of load isolating switches.

- Current transformer

The current transformer includes the following components and parts:

- primary winding

- cooling tubes

- transformer tank

- oil outlet valve

- secondary winding

- breather

- conservator

- cooling tubes and more

- Switched capacitor contractor

- Capacitor

It’s a series of parallel set of capacitors needed to enhance power factor of the system.

It serves as reactive power generations, and offer the required reactive power to obtain the active power of the circuit.

It lessens the amount of reactive power, and thus the overall power kVA.

- Lightning arrester

A lightning arrester is a most vital protective device of LV distribution system.

It safeguards valuable equipment and working personnel as well.

It discharges and arrests overvoltage to earth through lighting strokes.

Such are installed between earth and line close the equipment.

Transformer Distribution Component System

A transformer distribution is a transformer which presents the final voltage transformation in the electric distribution system.

It steps down the voltage utilized in the distribution lines to the level utilized by the customer.

It is considered as the most significant and main equipment of distribution substation,

It’s a static electrical device that steps down the primary voltage of 11kV or 33kV to the secondary distribution of 415 to 440 voltages.

CHAPTER 4: Package Unit Substation Installation & Maintenance

A well-managed electrical substation installation and maintenance guarantees:

- reduction in failures;

- and reliable supply

A lot of errors can be noticed during package substation maintenance routines.

It lessens the risk of massive plant downtime and avoiding future issues

Package substation installation

Basic Requirements for Package Unit Substation Operation

- The floor of the package unit-type equipment should be chosen at a higher place

You must avoid the low-lying place, to prevent rainwater pouring into the unit affecting operation.

When the concrete platform is poured, there should be a neutral gear to facilitate the laying of cables.

- There must be two reliable connections between the package unit and the grounding grid.

The transformer substation grounding and zero-connection can share a grounding grid.

The grounding grid usually drives grounding piles at the four corners of the foundation and then connects them into a whole.

- No illegal stacking around the equipment

Doing this will ensure the ventilation and operation of electrical equipment patrol needs the compact substation to natural wind circulation cooling.

Transformer door should not be blocked.

- Circle switch, transformer, lightning arrester, and other equipment in high-voltage distribution equipment should be inspected and maintained regularly

Defects should be found and repaired in time, and preventive insulation test should be conducted periodically.

The mechanical linkage should be appropriately removed, and the insulation rods should be operated.

Package Unit Substation Testing

Complete type and routine testing of the compact substation must be carried out as per IEC 61330.

For the type design test, the enclosure shall be capable of bringing short circuit forces because of 40kA symmetrical fault for one second.

Package substation testing

The temperature rise test must also be performed as per IEC 60431-1.

When the design type tests on the unit are done in the test laboratory of the manufacturer, such tests must be observed by a representative.

Every facility owner must have a documented and established program for the maintenance of every equipment vital to the reliable operation of the power system.

Further, preventive maintenance must be done at a level that guarantees that the unscheduled outage performance of customer-owned equipment.

Equipment Installation of Package Unit Substation

After the package unit substation is transported, following are the things you need to consider for the installation:

Package Unit Foundation and Peripheral Cleaning

Clean up the garbage and collapsed soil and rock around the package unit substation foundation.

Excavate the pre-buried high-voltage and low-voltage cable if it affects the installation of the package unit.

It should be according to the size of the package unit substation variable base on the package unit substation variable base to draw the substation variable base on the position of the four corners.

It must be marked with a clear cross symbol too.

The location of the crane and loading vehicle

The crane should be parked at the roadside where the truck is nearest to the truck.

The loader should be parked within the operation range of the crane.

That will ensure that the crane can smoothly change the trunk of the truck into hoisting, translating and lowering to the installation position within the operation range.

Adjustment of loading car inclination

After the loader stops stabilizing, if the inclination of the loader reaches more than 5 degrees, it is necessary to adjust the inclination of the loader.

That is, adding bricks under the wheel on the lower side of the terrain.

So the inclination of the loader can be adjusted to within 5 degrees.

After the adjustment of the inclination of the loading vehicle meets the requirements, the transverse section steel at the top of the substation changing steel frame structure will be demolished.

In demolition, it must be noted that the section steel must not fall naturally.

It must be removed manually to avoid damage to the substation shell caused by the section steel falling.

Top demolition of substation steel structure

As a final point, it is necessary to remove the fixed connection points between the substation transformer and the steel frame structure.

After the removal, it is necessary to check whether there are still undemolished fixed connection points.

You need to see the specific position of the substation changing lifting lug.

Package Unit Earthing

Earthing for a package unit substation includes four (4) earth electrodes in the easement.

It also has three (3) earth electrodes in the cable entry trench.

You see, in the easement, 4 bore holes to be drilled at corners, along with a distance of 2.7 meter apart for every hole

-Bore depth is 3 meters

-Auger diameter to be utilized shouldn’t be more than 150 millimeters

-Earth electrodes must be made from either bar 70 square millimeters copper conductor with an earth stake connected through a profile “6” compression connector.

Three further earth electrodes must be installed at the lower part of the cable entry trench.

It should have a distance of 6 meters in the middle of electrodes and to a depth of 3 meters.

Hoisting of Package Unit Substation

After the top section steel and the fixed connection point of the package unit structure are removed smoothly, the crane hook is reliably connected with the lug by four equal-length slings.

Then the crane slowly lifts the hook.

The hook must be lifted in a vertical position, not inclined or inclined.

When the cabinet becomes suspended, the crane’s pulling force will be received.

When the cabinet becomes suspended, the wire rope will not shake.

The boom will be fine-tuned to ensure that the swing amplitude of the cabinet will be too large before and after the cabinet becomes suspended.

Collision with the steel structure will damage the cabinet.

After fine-tuning, you need to continue to lift the hook, lifting package unit to change the bottom from the steel structure about 30 cm away from the support point.

You need to stop hoisting hook not less than 30 seconds.

Make sure to check the safety of the suspension belt, as well as the suitability of each force point, whether the force is uniform.

Ensure to determine that the various parts of the problem-free case can continue to lift.

When the compact unit is moved to the base of the compact unit into reinforced concrete, the hook is slowly lowered until the compact substation is about 0.5 meters away from the ground.

The hook stops lowering and adjusts the direction of the unit reasonably.

Slowly down, the four corners of the prefabricated compact substation are all set to one person to adjust the angle and position at any time.

That will ensure that the seat of the prefabricated substation is aligned with the painted cross symbols until the transformer becomes completely down.

If the base position is not aligned with the position of the cross symbol, the substation should be re-elevated to an appropriate height.

Moreover, the boom should be lowered, and the angle position should be adjusted until the substation is completely lowered and aligned with the position of the cross symbol.

After the compact unit is completely put down, it is necessary to measure whether the unit is stable or not and whether the package unit is level.

If there is any problem, it is necessary to add steel plate under the unit until the package substation becomes stable.

Package Unit Substation Maintenance

Maintenance programs can differ in the array from severe adherence to the manufacturer’s suggestions to Reliability Centered Maintenance, as needed.

Package substation maintenance

However, it must mirror Good Utility Practice as well.

The maintenance of equipment must be done such that the owner can support any national interconnection agreements.

Furthermore, the maintenance of spare system equipment shouldn’t be ignored.

Package unit substation must be kept by certified personnel by appropriate industry standards as well as Good Utility Practice.

You see:

It will offer maximum reliability and operating performance.

Improper operation of the equipment must be investigated thoroughly.

It must be documented as well to identify the cause of the issue in connection with the disrupted Transmission Owners.

Routine Maintenance and Overhaul of Fans

Check the operation of the fan.

If not running, you can use the temperature and humidity controller.

Make sure to adjust to the existing temperature below, start the fan check.

Maintenance and Overhaul of High Voltage Switch and Low Voltage Switch Electric Operation Mechanism

- Check the barometer pointer. If it is in the green area, if it enters the red area, switch on and off operation. Inform the manufacturer immediately for processing.

- The lubrication of mechanical parts and components can be completed by using general lithium grease (butter) lubrication after the splitting operation test.

- Routine tests of cables and arresters.

According to routine test requirements, insulation test and leakage current test for cable and lightning arrester are carried out.

Auxiliary Routine Test

- Conduct a routine test of temperature and humidity controller

- Conduct a routine test of the smoke alarm device

- Tightening and inspection of terminal row

- Tightening and inspection of standard parts.

Terminal Maintenance

The terminal row may be loosened due to thermal expansion and cold contraction.

The annual inspection should be conducted to tighten all terminals in the terminal room.

NOTE!!

Before re-fastening, please confirm that the AC circuit and the two control loop are all cut off.

Doing this so will avoid electric shock.

CONCLUSION

Whether you are a:

- Consultant

- Panel builder

- Specifier

- Contractor or;

- End-user

Simplify your package unit substation buying process by understanding the fundamentals.

Make sure that you read this comprehensive guide on Package Unit Substation carefully

The changes are that you won’t need to waste your precious time searching any further.

What are your ideas?

Share your thoughts with us today by contacting us.