Introduction

An electric power system utilized in association with the term switchgear talks about the combination of:

- fuses

- electrical disconnects

- circuit breakers

Such electrical switchgear is utilized to clear faults downstream.

It can also be used to de-energize equipment.

That enables work to be done on the equipment.

In this post, we will guide you on everything you need to know about electrical switchgear.

Throughout this guide, you will get to know:

- Chapter1: What is electrical switchgear

- Chapter2: Electrical switchgear design

- Chapter3: Electrical switchgear diagram

- Chapter4: Types of switchgear in the electrical system

- Chapter5: Electrical switchgear components

- Chapter6: Electrical switchgear installation

- Chapter7: Electrical switchgear maintenance

Now, without further ado, let’s start discussing the basics of electrical switchgear.

In the first chapter, let’s talk about the definition of electrical switchgear.

Chapter 1: Electrical Switchgear Definition: What is Electrical Switchgear?

What is Electrical Switchgear?

For those who do not know, electrical switchgear is a broad term.

It is a generic term that is composed of a series of switching devices.

These are utilized to:

- meter

- regulate and;

- control your power system

Perhaps you had seen switchgear before, even if you did not realize it.

Some of the examples of the switchgear devices include:

- control panels

- lightning arresters

- indicating instrument

- potential and current transformer

- relays

- isolator

- circuit breaker

- fuses and;

- switches

You see,

The switchgear system is directly connected to the supply system.

It is located in both the low voltage and high voltage side of the power transformer.

It is utilized for de-energizing the equipment for:

- maintenance

- testing and

- for clearing the fault

What Does Electrical Switchgear Mean

It is composed of the combination of those switching devices along with associated:

- regulating

- measuring

- control and;

- protecting of equipment

The switchgear devices, as well as their assemblies, are utilized in the:

- generation

- transmission

- conversion and

- distribution of electrical energy

Chapter1: Electrical Switchgear Working Principle:How Does Electrical Switchgear Work?

When the fault takes place in the power system, heavy current flow through equipment.

That caused the equipment to get damaged.

You see;

The equipment also gets interrupted.

Therefore,

To safeguard the lines, transformers and generators form any damage, switchgear devices are needed.

The automatic protective switchgear is composed of the circuit breaker and relay.

When the fault happens in any part of the system, the relay of that pat comes into operation.

It closes the trip circuit of the break that disconnects the faulty region.

The healthy section remains supplying loads.

Therefore,

There’s no damage to equipment and no interruption of supply.

Chapter 2: Electrical Switchgear Design

Electrical switchgear is safe to touch.

This is thanks to its earthed metal enclosure.

HV HRC fuses, as well as cable terminations, are accessible when branch circuits are earthed.

The operation is available when the enclosure is sealed completely and other doors closed.

It has a maintenance-free pressure concentration arrangement.

It is laid out as a special cooling system.

It lowers the thermal and pressure-related effects of an arc fault.

This is to make sure that the building and personnel are safe.

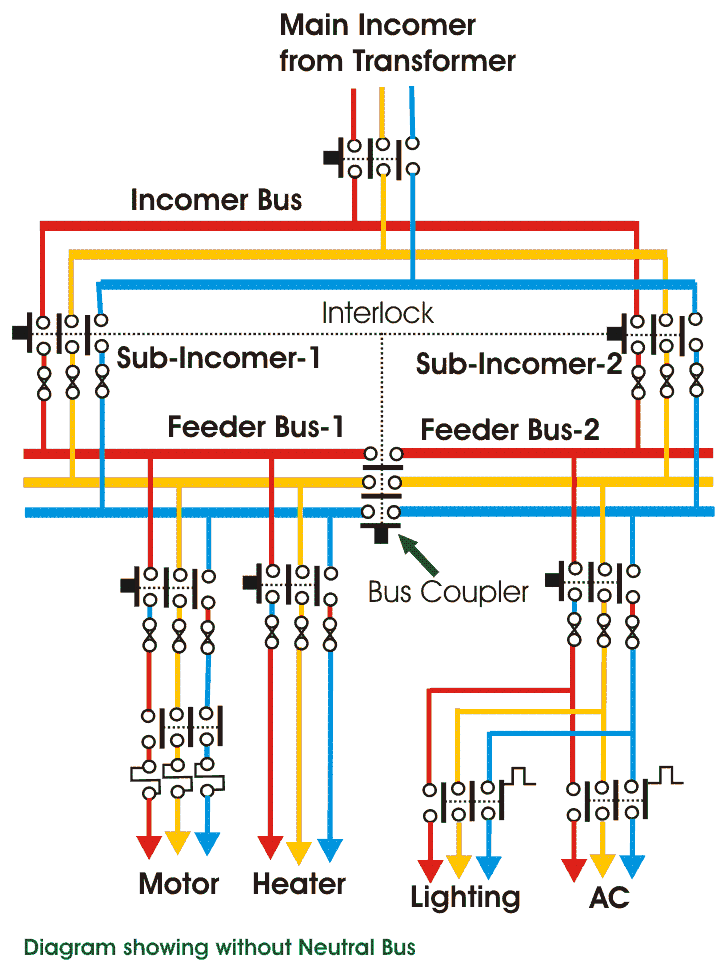

Chapter 3: Electrical Switchgear Diagram

You see,

There is more to switchgear than the circuit breaker.

Aside from the functionality and component, the system needs to carry and switch it to various subsystems and particular machines within your facility.

It also requires some means of metering.

It must perform the same functions.

From one end to another, the switchgear system would require to include:

- 1 or more circuit breakers

- voltage transformer

- current transformer

Some sort of protection relay as well as a measuring instrument.

It would also require:

- a lightning arrestor

- fuses

- electrical switches and an

- electrical isolator

Below is an example of an electrical switchgear diagram:

Chapter 4: Types of Switchgear in Electrical System

In case you didn’t know yet;

Switchgear is categorized into two kinds:

- the indoor type;

- the outdoor type

For voltage more than 66kV, the output switchgear is utilized.

Due to the high voltage, the building work will needlessly raise the installation expense owing to:

- big size of insulators

- big spacing between the conductor

Those under the 66kV, there’s no complexity in offering the building work for the switchgear at a fair cost.

The indoor type of electrical switchgear is of metal clad type and is always compact.

Due to compactness, the safety clearance for operation is lowered as well.

Therefore, it lowered the area needed.

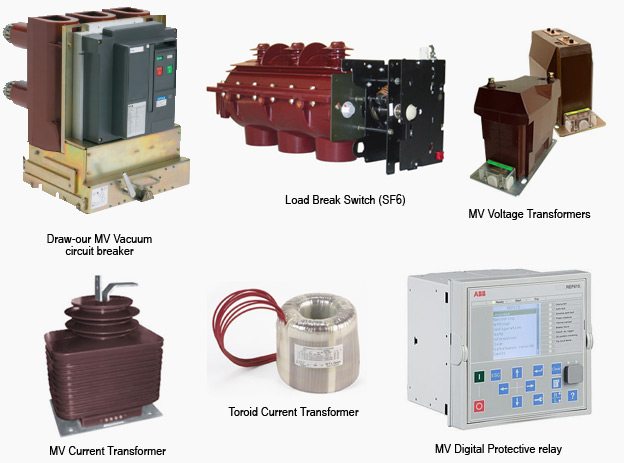

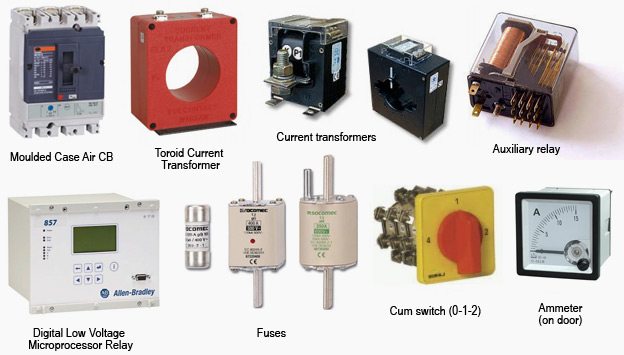

Chapter 5: Electrical Switchgear Components

Essentially, switchgear is composed of protecting and switching devices like:

- auto reclosures

- potential transformers

- current transformers

- lightning arrestors

- control panels

- protective relays

- circuit breakers

- isolators

- fuses and switches

You will find some types of equipment that are made to operate under both abnormal and normal cases.

Several types of equipment are intended for switching and not tracking the fault.

Throughout the normal application, switchgear allows to switch off or on:

- distributors,

- transmission lines

- generators and;

- other electrical equipment

Meanwhile,

When a failure takes place on any area of the power system, a huge current flows over the equipment.

That threatens damage to the equipment and interruption of service to the clients.

Nevertheless,

The switchgear tracks the fault.

It disconnects the unhealthy area from the system.

Likewise, current interrupting and switching devices play a vital role in the:

- modern network

- load centers

- distribution substation

- substations at various voltages

- transmission substations

- generating substations

You see;

The switching device here is referred to as a circuit breaker.

This device, together with associated devices for control regulation, metering and protection are known as switchgear.

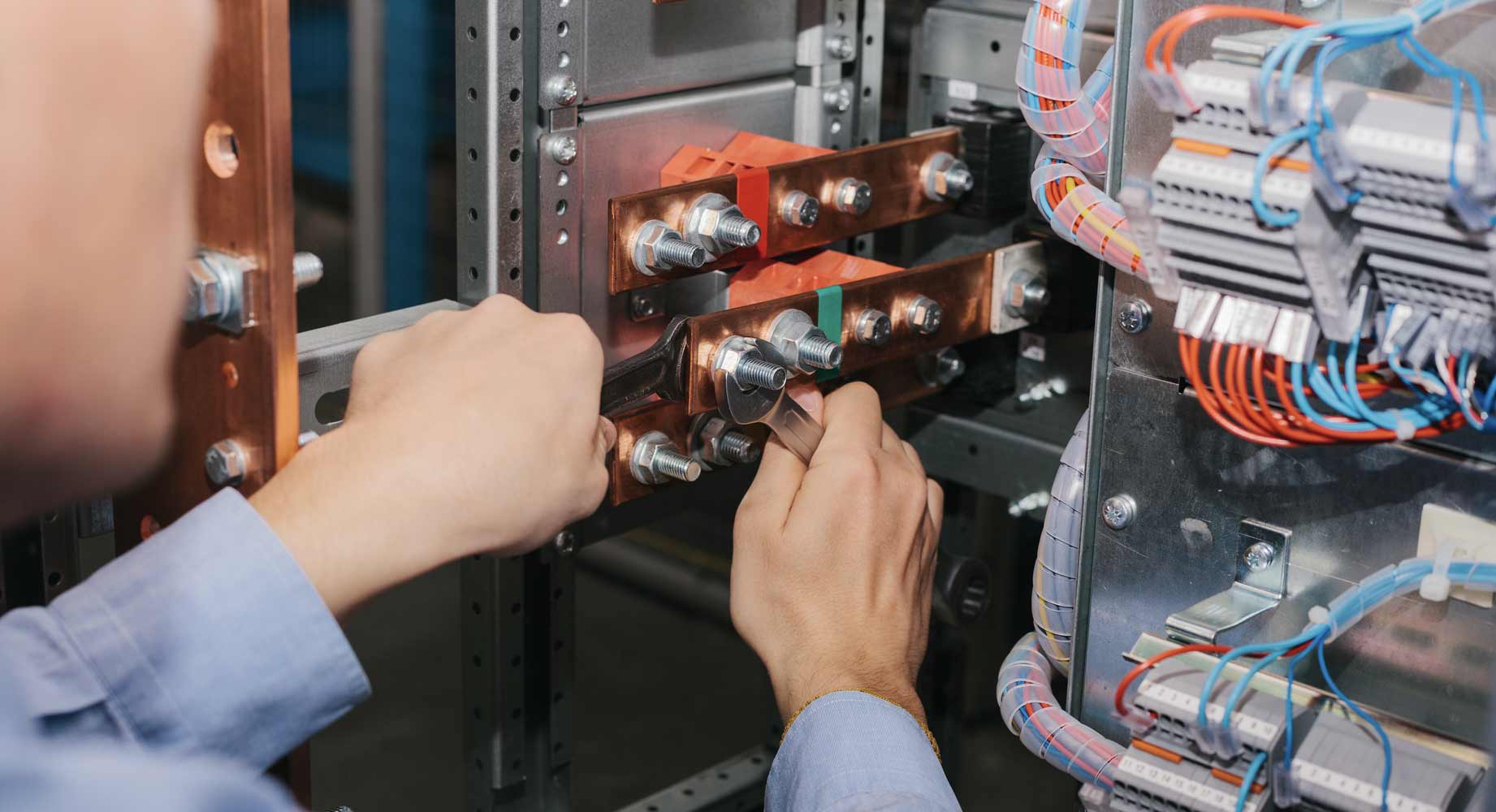

Chapter 6: Electrical Switchgear Installation: How To Install Electrical Switchgear

Before installation, you need to make the perfect foundation for it.

No matter if it’s outdoor or indoor, pilings or concrete, the foundation should have a smooth level surface.

- Measure the surface where you like to install your switchgear along with a tape measure.

- Draw a line and outline it.

- Make the holes in areas on the wall, which will be behind your switchgear.

Start drilling one-half inch diameter holes into the wall.

You can insert the cable sleeve into every hole and tap the cable sleeve to the holes.

Don’t forget to tighten the anchor bolts along with the socket wrench.

- Set your low frame in position on the surface.

- Connect a nut into every anchor bolt.

- Connect the power cables to the switchgear cubicle.

Take note that this the unit which will be positioned on top of the low frame.

Route the power cables into your lower frame.

You can secure them to your cable brackets long with a cable clamp.

- Get rid of the plastic cover and any sort of strappings on the switchgear cubicle.

You can also disconnect the sensor cable from your sensor cable connector.

- Slowly raise your cubicle up into position via a service trolley.

Secure the switchgear cubicle by placing the bolts in the bolt holes.

Don’t forget to tighten every bolt with a socket wrench.

Finish all the wiring and cable connections.

After this, you’re good to go.

Chapter 7: Electrical Switchgear Maintenance

Did you know?

Preventive maintenance is the answer in maintaining your switchgear working properly.

It is suggested that each year, all of the:

- disconnect points

- circuit breakers

- switches

be manually worked and tested to guarantee they are working properly.

Having a visual inspection is crucial to check for any debris or dust.

It’s also vital for discoloration or tightness in any of the parts.

When doing this kind of maintenance, the longevity of the switchgear power systems could be raised.

Remember:

Installation of dust-free ventilation systems and dehumidifiers can also lower several factors.

In fact, it can lower the performance of the power system.

It might also cause system failure because of the damage.

For the yearly procedure, make sure you inspect:

- switches

- disconnects and;

- circuit breakers

To lower vibration, you can re-tighten every mounting bolt.

You need to assess every termination for tightness.

Also:

This one is something you should not ignore – the temperature of the facility or switch room.

Switchgear is extremely sensitive to changes in the temperature.

You need to assess the:

- thermostats

- temperature control panels

- and the actual temperature of the room

This is to know if it’s within the right operating parameters needed by the equipment.

Normally, switchgear power systems are low maintenance kind of equipment.

However, that must not stop it from getting attention at least once a year.

Although the equipment can work smoothly for some years without an inspection, the failure of your system could’ve been avoided with some basic yearly maintenance.

You need to get into the yearly inspection routine and save yourself the expense of new equipment installation.

In short:

Having a simple maintenance routine every year can highly prolong the lifespan of your equipment.

It can reduce the likelihood of malfunctions caused by fixed items, which need a small amount of attention.

Conclusion

What do you think?

Have we answered some of your basic questions about electrical switchgear?

If not, feel free to share your concerns about us by leaving your comments below.

We will be so much happy to answer all of them.

Share this guide to your colleagues and friends who are searching for answers about electrical switchgear.