RMU Ring Main Unit

The ring main unit(RMU) is an electrical device applied to the power supply unit of the secondary distribution system. The function of the ring main unit(rmu) is to connect the loop network and improve the reliability of the power supply, such as the loop operation of the loop network or the load cut of the ring network.

The most important components inside of the ring main unit are the load breaker switch and fuse, which can provide fault protection for the loop network and improve the operational safety of power supply lines.

There are mainly 3 types of ring main unit(rmu) classifications according to isolation medium in the market:

SF6 Gas isolation, air isolation, and solid isolation.

Orecco Ring main unit is simple in structure and small in volume and requires less application area. The ring main unit has the advantages of low price, low maintenance cost, good cost performance, good operation reliability, and can improve the power supply parameters.

The ring main unit is small in size and can adapt to all kinds of buildings. It can be used for long-term stable power supply and infrequent high voltage switching operation. So ring the main unit is now widely used in residential buildings, public places, factory buildings and other buildings, especially in medium and small capacity compact stations.

Applications For RMU Ring Main Unit

Ring Main Unit(RMU): Definitive Guide

What is a ring main unit?

How does ring main unit work?

What is the ring main unit in electrical power distribution?

Perhaps, these are the most typical questions you ask yourself if you are planning to enter the RMU market.

The basic of ring main unit can be simple.

However, once you start digging, you’ll surely feel overwhelmed with the ring main unit construction, ring main unit configuration, ring main unit installation details and a lot more!

So, how can you handle that?

Luckily, this e-book about the definitive guide to ring main unit, you’ll access all the information you need to get started.

Do you think we’re exaggerating?

No, unfortunately, we’re not.

If you want to be certain, there’s only one way to find out.

So what is it?

Well, it depends on your hands now.

Start reading this guide today so you’ll know what ring main units is and how it can benefit you.

Enjoy reading!

- Ring Main Unit (RMU) Definition

- Ring Main Unit Working Principle

- Ring Main Unit Circuit Wiring Diagram

- Ring Main Unit Types: The Classification of Ring Main Unit

- Ring Main Unit Function: The Applications of Ring Main Unit

- Ring Main Unit Components

- RMU Testing Procedure: How to Test a Ring Main Unit?

- RMU Maintenance & Operations: The Definitive Guide

- Conclusion

Chapter 1: Ring Main Unit (RMU) Definition: What is a Ring Main Unit (RMU)?

In line with the increasing demand for a reliable and secure source of power supply in developing regions like Asia Pacific, the demand for ring main unit in smart grids and distribution utility segments is also expected to rise significantly.

This compact switchgear unit has the ability to minimize power loss and provide uninterrupted power supply to meet the growing needs for electricity and capacity addition.

Ring Main Unit (RMU) Definition

When talking about voltage power distribution, you might have probably encountered the acronym RMU and ask yourself:

What does RMU stands for?

Ring Main Unit

The ring main unit, also known as the ring network power supply unit, is a set of high-voltage switchgear installed in a steel plate metal cabinet or made into a modular compartment.

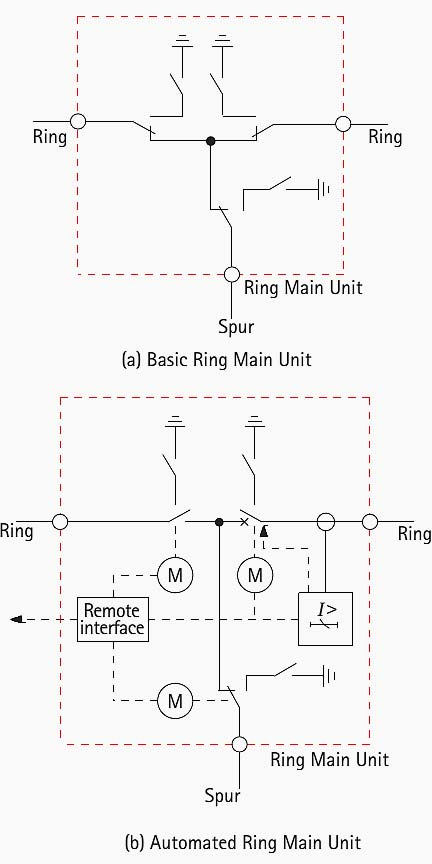

The core part uses load switches and fuses. Each ring main unit is a flexible connection mode formed by 3 to 5 total switch boxes to meet the power supply requirements of different power distribution network nodes.

Since the power switch device and the hard bus are packaged in the same closed metal casing, generally used as insulation and arc extinguishing medium, the switch adopts three-phase linkage three-station SF6 gas load switch or circuit breaker, and the high-performance spring mechanism can realize fast switching operation.

A single ring main unit is composed of different modules and busbar units such as the incoming unit, the measuring unit, and the TV unit, and various combinations can be arbitrarily combined according to actual needs.

With the use of ring main units, one does not need to worry in case there is a failure in the first source of power supply since power supply recovery can happen very quickly with the help of the second source.

Each ring main unit includes:

- An incoming feeder that is either a vacuum or SF6 circuit breaker;

- Two or more outgoing feeders composed of load break switches used for cable connection

Due to its versatility, safety and budget-friendly maintenance, it is often preferred over conventional switchgears.

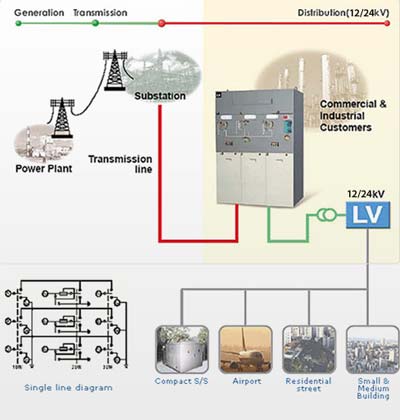

What is ring main unit in electrical power distribution?

Ring main unit in electrical power distribution

The ring main unit(RMU) is a secondary power distribution equipment. The secondary power distribution equipment refers to the medium voltage switchgear that redistributes the electrical energy of the primary power distribution equipment that receives the high voltage transformer.

The basic component of the secondary power distribution equipment is the load switch. And current-limiting fuses are not only economical, but also have good protection characteristics (such as current-limiting fuse protection transformers).

At the same time, with the increase in the capacity of single users, many circuit breaker solutions are also used.

Among all sorts of ring main units, gas insulated RMUs have the highest insulating capacity and can be easily integrated to an existing secondary distribution system.

Types of Ring Main Unit

Ring main units can be classified according to type, application or geographical setting. As cited in Market Research Future, there are basically four classifications of ring main units by type:

- Gas insulated;

- Oil insulated;

- Air insulated;

- Solid dielectric insulated

While each of these are used to optimize performance and improve the availability of energy on distribution utilities and industries; they all differ in size and capacity.

That is why in choosing for the right ring main unit to use in your secondary distribution substation, you will have to consider first what type of unit you are going to use how much space the ring main unit would take up upon installation.

Aside from that, gas insulated ring main units are widely used in power grids and railway systems as they can cover minimum floor space, are more packed in, safe to use, can be installed easily, and are less prone to external influences.

Oil insulated ring main units, on the other hand, are ideal for rural and industrial settings as they are highly versatile for both indoor and outdoor purposes.

Some oil insulated RMU providers include non-extensible, extensible and modular options that can be incorporated even in the most extreme conditions.

Air insulated ring main unit are highly reliable and smooth despite reducing a number of components.

The following are some of its features:

Modular

Can be applied easily into your substation

Utilizes modern ring main unit design

Most RMU manufacturers have strived to develop environment and user-friendly air insulation models that will stand through generations.

Solid insulated RMUs are more compact and environmentally safer. They are built as logical choices for consumers using medium voltage distribution systems.

So if you want to provide power for up to 24kV substations, solid insulated ring main units will be probably a good option.

Functions of Ring Main Unit

As mentioned before, ring main units are used primarily in electrical power distribution systems for an uninterrupted power supply. It enables the user to obtain power supply from two high tension power sources at the same metering point.

A standard ring main unit typically consists of three switches, two of which receives incoming and one distributes outgoing medium voltage supplies.

Aside from switching the power cable rings, it also helps in protecting your secondary side transformer from the occasional transient currents.

Depending on the applications and load requirements, you can either use a combination of switch fuses or an isolator, which are attached on both sides of the secondary side transformer or the T off.

Ring main units usually come in standard ratings of 11/22/33kV.

Advantages of Ring Main Unit

You might be probably asking:

What are the advantages can I possibly gain from using a ring main unit for my substation? Or does it make sense if I use a ring main unit instead of having a radial distribution system?

The advantages listed as following:

Adopt sf6 gas as the insulation medium, it great improved insulation and arc extinguishing performance .

Compact structure design, small dimension, which is conducive to miniaturization.

Adopt fully-sealed structure, the core components not influenced by external environment.

The design of free maintenance structure, reduced the maintenance cost.

One thing that makes the difference:

Ring main units assure its consumers a greater security of power supply loaded onto their secondary distribution systems. If you haven’t noticed yet, all the distribution bus bars are supplied at both ends of the ring.

This can only mean two things:

First, the device can be immediately isolated whenever a fault develops on any part of the unit.

Second, the electrical power supply will continue to be fed to the bus bars even the ring main unit is completely broken.

While radial distribution systems have only one simultaneous path for voltage supply, the ring main distribution system includes various substations that are interconnected through alternate routes.

In case a particular section fails or becomes subject to damage, it can be easily disconnected for repair and the power will still be supplied on both ends of the ring.

Ring Main Unit VS Switchgear: What’s the Difference?

Depending on the application and site conditions, the concept of a ring main unit and switchgear can sometimes come at the same point, but cannot be used interchangeably.

While both are generally used in medium voltage, a ring main unit only has a circuit breaker to switch the secondary side transformer from the ring while a switchgear has three circuit breakers that could switch all parts of the circuit.

Switchgears are also more versatile as compared to a ring main unit since you can conveniently add more circuits without requiring a load of too many cables.

However, what makes ring main units ideal for consumers is that it can be installed at different substations, containing three switches that connects the transformer or other equipment within the distribution system to the device.

If one cable fails, a substation is still provided with power supply on a different direction. Switchgear can only be applied to a single substation directly supplied by the power source.

Although ring main units are more expensive than switchgears because of its special configuration, just think that RMU can be a switchgear itself as it can be fused, contracted or operated with a circuit breaker.

Chapter 2: Ring Main Unit Working Principle: How Does a Ring Main Unit Work?

As discussed in the previous chapter, a ring main unit is a two-way power source integrated into a secondary distribution system. It is used primarily to provide an uninterrupted voltage supply from two directions and thus, improving its reliability.

Apart from the classifications, uses, and forecasts, you have also been probably intrigued by how a ring main unit actually works. How does it exactly perform its roles in our substation?

Well, let’s start with the basics.

Why Do We Use Ring Main Unit?

Ring main unit at its core is used by consumers for its two major advantages:

First, the ring main unit is to prevent the voltage supply from dropping off at various load substation. In a typical urban ring main arrangement, the loss of supply is immediately replenished through manual switching.

Second, it increases the reliability of medium voltage supply in case one of its section fails to function. For each substation, there is always a “firm” supply or an alternative path available.

Despite being at the same metering point, both ends of the ring are capable of supplying power in every substation located within the ring.

Ring main units have the same level of reliability as that of parallel distribution feeder systems, however, they support larger load substation and are cabled on different pathways.

Key areas that are powered through ring networks include:

- Airports and underground railway stations

- Commercial buildings

- Compact substation

- Industrial and mining enterprises

- Oil refineries

- Ports

- Residential quarters

- Wind and solar power generators

Some distribution systems with small load capacity (e.g. 11kV substation) require loops that are equipped with high-voltage fuse protection.

What is RMU in substation?

Ring main unit in substation

The substation is one of the terminal for ring main unit, there are two incoming power lines enter into ring main unit synchronous, one line for supplying user, another line for standby, it make the power supply net into ring circuit to ensure the power supply reliability.

Ring Main Unit Working Principle

A ring main unit allows its users to obtain a continuous medium voltage power supply from two alternative directions.

For such reason, it is considered as a flexible power source in electrical distribution systems.

The voltage distributed throughout the ring circuit is called the ring network power supply which is sufficient enough to drive critical loads or activities such as oil refinements and solar power generation.

Through the power supply transmission lines, the voltage is supplied towards the ring trunk. It is then distributed through the trunk line until it reaches the load switches.

These load switches are responsible for obtaining and distributing the ring network power supply from the mains supply to the secondary distribution system.

Among the advantages of ring main unit also is its capability to supply power from the left and the right trunk to each of its distribution branches.

Although we can say that the ring network is supplied just by a single circuit, it is similar to other two-way power supplies which enhances the reliability of power distribution throughout the substation.

To make it short:

Once the right trunk fails to supply, the entire system can still depend on the medium voltage supply provided by the left trunk. The same goes when the left trunk fails to do its job.

It is also safer. Why?

When one section suffers damage, you can easily disconnect it from the system and conduct a repair while the rest of its components continues to supply the ring.

Ring Main Unit Types Based on Protection

There are basically three classifications of ring main unit based on their shielding components:

- Fuse type

- Breaker type

- Disconnection type

While they are almost the same in terms of protection capabilities, they can vary with the cost they can incur to the consumers and also the load substation they can handle.

Fuse type ring main units are said to be the most cost-efficient type of feeders that can provide overcurrent and earth fault protection to distribution systems running with up to 2000kVA transformer.

Fuse type module

They work best especially when they are paired up with circuit breaker type ring main units.

Fuse type RMUs are propelled by trip coils attached from the protection current transformer. Thus, whenever a fault happens, it can be easily broken and the fault current will be shifted towards the trip coil, slipping the circuit breaker off.

Sometimes, consumers may think that they can use fuse type ring main units to limit the overload levels of their transformers, but this may lead to a wrong way.

Fuse type ring main units are designed to be used only for fault protection.

Another type of ring main unit makes use of a self-powered breaker relay protection, which is also designed to protect the transformer or the downstream network from fault currents.

Some breaker type ring main unit manufacturers include the following features:

- Thermal load protection

- Earth fault protection

- Optional password for more complete and assured control of devices

- Added tripping functionality and Modbus protocol support

- Recording and measurement of fault currents

Breaker type RMUs can also support a wide range of transformers and can prop up with diverse industrial applications.

They also require simple operations and lesser charges on maintenance.

A disconnection type ring main unit, on the other hand, can manually protect the device from internal fault and isolate a section of it in case there is something needed to be worked on the transformer.

As the name suggests, it uses switch disconnectors as its primary switching device.

Chapter 3: Ring Main Unit Circuit Wiring Diagram: How to Wire a Ring Main Unit?

If you want to power up your distribution system, one of the basic things you must learn is how to wire a ring main unit and stream it into your substation.

Of course, there are a number of rules and a set of standards you must adhere to perform this electrical work successfully. After all, what defines a ring main unit is how it is properly wired and coordinated within your distribution system.

Upon reading this chapter, you are expected to:

- Know the procedures and preparations in wiring a ring main unit

- Recognize the importance of a proper wiring of ring main to consumer unit

- Learn the regulations that must be observed in the process of wiring

Ring Main Unit Circuit Wiring diagram

While three lines and four lines wiring are used in some complex ring main networks, the most widely used are the single line wiring and double lines wiring.

Ring main unit circuit diagram

Single line ring main unit wiring involves a second bus line of either the same or different bus sections of the substation or switch station. Two loops are installed to simultaneously provide power into the inner loop load.

As discussed earlier, one of the advantages of the ring main unit is its versatility. When one of these loops fail to perform its function, the other loop can still work for the consumer unit. This makes ring main units crucial for heavily loaded distribution systems.

Feeding the cables through the cavity may expose it to moisture, driving it towards a larger possibility of insulation break down or damage.

Ring Circuit Diagram Advantages

The advantage of ring main distribution system compare with radial circuit system:

- There is power supply in both end of the ring main circuit system.

- If there is a fault in radial circuit system, the entire system will be power off, but in ring main circuit system, if one end occurred fault, the other end still provide power supply for using.

- The voltage drop is less in ring circuit system

Rules in Wiring a Ring Main Circuit

A ring main unit is not a ring main unit if the cables are not installed properly. According to DIY Data, the name “ring” itself was derived from the circling formation of the ring main cables going from the consumer unit to the sockets.

Ring main circuit wiring

Below are some of the mistakes often made in wiring a ring main circuit, which often leads to system failure and risks:

- Disconnecting the ring network from the segment switch

- Contact between wiring and dual power plus bus bar

- Disconnecting the switch station in the access ring network system by the bus bar segmentation switch

- Equipping the power supply side of the ring main unit network with earthing switch, lightning arrester, live display and current transformer

Many manufacturers and users often ignore these issues, which are in fact, crucial in the entire wiring process. Improper wiring and misoperation can cause accident and even affect the efficiency and safety of the power supply.

To avoid these complications, the power supply side must not be equipped with a grounding switch. A load switch is already made of three stations, which contains the grounding switch.

Now, if we will add more grounding switches, these could lead to an interlocking problem and further increases the complexity of the cabinet.

Furthermore, it is also not necessary to install a lightning arrester especially if the ring main network lines are laid underground and the cables are encased in metal sheath.

In cases wherein the load current is in the open section and the operation overvoltage and interception are minimal, it is also not essential to have an overvoltage protection device.

Live displays are also needed in order to observe whether or not the incoming line is energized. This step is particularly performed especially when there is no voltage transformer and voltmeter installed in the circuit.

Do you need to worry about the cost of having this equipment?

Good question. Of course, no. In fact, you can allocate a minimal amount to invest in these live displays. Plus, the sensors of these equipment support insulators.

If you happened to install a microcomputer terminal measurement or control device along with your switch station, you also must have the current transformer to provide a current symbol.

Ring main unit cables

What size cable to use for ring main unit wiring?

- The thickness of the cable, only determines the current carrying capacity; for the use of safe electricity, mainly determined by the switch inside the ring main unit, or microcomputer protection and fuses.

- The incoming and outgoing cable specifications are the same, not to say that their current is the same, but the theoretical current carrying capacity is the same. For example, a motorized vehicle can run at a high speed (incoming line), or it can run the national road (outline), except that the driving speed (current passing) has its own requirements.

- It is safe when the load on the line does not exceed the nominal current of the cable .

In general, the recommendations:

- The most insured according to the design drawings of the wiring diagram. If there is no paper map modification project, refer to the original cable specifications or re-calculate the final load.

- Verify how much capacity is allocated by the superior switch station to further implement safe power.

Chapter 4: Ring Main Unit Types: The Classification of Ring Main Unit

There are dozens of ring main unit available for use in various applications, and most of these consumer units can either fall into one or more types designed using a particular set of materials.

By recognizing the different classification of the ring main unit you are about to purchase, you cannot only identify the characteristics, but also determine the right product for a given application.

Ring Main Unit (RMU) Types Classified by Function

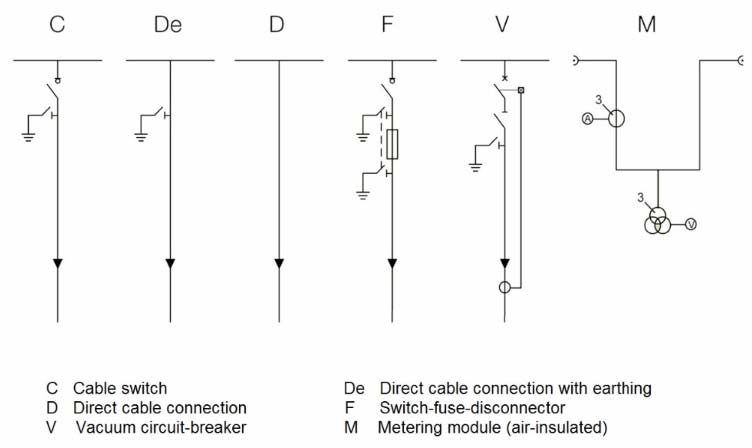

Ring main units are typically divided into nine (9) basic classifications based on their functions:

- Cable switch module (C)

- Switch fuse-disconnector module (F)

- Vacuum circuit breaker module (V)

- Cable entry module (B)

- Measuring module (M2)

- Female module (I)

- Cable entry cabinet (A2)

- Pressure change module (CPT)

- Pressure change module (APT1)

These types all differ in their protection capabilities and how they are applied in cable control, branching, and segmentation.

Cable switch module, or C Module, is a ring main unit module used in making cable in and out line connection, branching, segmentation and control.

It is the similar to the V Module; however, the latter can only be applied for control and protection of distribution transformers that accommodate large voltage capacities.

Switch fuse-disconnector module, or the F Module, is an RMU module whose primary function is to control and protect terminal distribution transformers with smaller voltage capacities ranging from 1250kVA and lower.

Fuse module type

Two RMU module types, namely cable entry module and cable entry cabinet, are used in the introduction of cable entry. Cable entry module is applied on SF6 gas-insulated consumer units where the high pressure part can be found mainly on the SF6 gas.

Cable entry cabinet, on the other hand, is applied on air-insulated ring main units, where the metal-encased cable connector is directly connected to the bus bar.

Measuring module is another classification, used mainly in power supply department incoming line metering. Like cable entry cabinets, this RMU module is applied mostly on air insulated consumer units.

For the segmentation and communication of two bus bars within the consumer unit, the female or I module is used.

Pressure change modules are classified into two types, both used in driving motor lighting equipment.

- CPT Module

- APT 1 Module

The former is often equipped with load switches necessary for PT maintenance and overhaul.

Types of RMU Classified By Location

Ring main units can be classified using their location, or the place where they are stationed or installed. There are generally two types of ring main unit for this category:

- Indoor ring main unit

- Outdoor ring main unit

Outdoor ring main unit

As the name suggests, indoor ring main units are based within buildings or under covers. According to BVM Technologies, indoor RMUs are best for the following applications:

- Compact secondary distribution systems

- Small-scale industries

- Wind power plants

- Modern establishments such as hotels, buildings, and business centers

- Light mining applications

- Public and private set ups such as airports, hospitals, tunnels and underground railways

Outdoor ring main units on the other hand, are more compact and usually equipped with safety features against changing atmospheric conditions. Most outdoor RMUs are furnished with virtual maintenance-free systems.

Ring main unit types Classified by Protection

Setting indoor and outdoor ring main units aside, consumer units can also be classified according to their insulation. Market Research Future mentioned that there are normally four types of ring main unit based on insulation.

- Oil insulated ring main unit

- Gas insulated ring main unit

- Air insulated ring main unit

- Solid dielectric insulated

All of these ring main units have the ability to improve the reliability of voltage supply within distribution utilities and industries. However, they differ on size and their capacity.

For one, gas insulated ring main units have the highest insulating capacity while occupying the least floor space required for a particular consumer unit.

It is really necessary to choose the right insulated ring main unit for your secondary distribution system as it can affect its efficiency and overall performance.

Most ring main unit consumers take consideration not only the energy it can afford but also the space it will take up in the substation.

Gas insulated ring main units, are among the most widely used consumer units as they can cover a minimum floor space, are more compact, equipped with safety features and can be easily installed within the distribution network.

Because gas insulated RMUs are also secured from external influences, they are also the ones used in power grids and railway systems.

Oil insulated ring main units are known for their high versatility, and having one would save you from buying two separate indoor and outdoor RMUs as they can be used in both applications.

These ring main units are also ideal for rural and industrial settings. Some oil insulated RMU manufacturers provide non-extensible, extensible and modular options that can be incorporated even in the most extreme conditions.

Air insulated ring main units on the other hand can work smoothly even reducing a number of its components. They are modular, can be easily applied within the substation and are made using modern ring main unit designs.

Most of these ring main units are durable and can hold for long periods under extreme conditions.

In fact, RMU manufacturers are already on their way of developing environment and user-friendly air insulated RMUs that can stand through generations.

The last type of insulated ring main unit is the solid dielectric, which are way safer compared to the three. They are built for voltage distribution systems with power requirement as high as 24kV.

Ring Main Unit Types Classified by Protection

As mentioned in the second chapter, ring main units can also be classified based to their shielding components, or materials that are used to intensify their protection capabilities.

There are three types of ring main unit under this category:

- Fuse type ring main unit

- Breaker type ring main unit

- Disconnection type ring main unit

All these types differ in their capacity, which means that it can support only a limited number of load substations. These ring main units also vary with the cost they can incur to the consumers.

Among the ring main unit types, the fuse type ring main unit is the most cost-efficient and can support up to 2000kVA distribution substations.

Breaker type ring main units are used especially in protecting the ring main network from fault currents. Some breaker type RMU manufacturers offer features such as thermal and earth fault protection designed for this purpose.

Disconnection ring main units, meanwhile, use switch disconnectors as its primary switching device.

It can manually protect the device in case something is needed to be worked on the transformer.

Ring Main unit Classification by Number of Configurations

Ring main units can also be classified based on the number of their configuration, which could go as high as 10. Among these consumer units are the 3 way, 4 way and 5 way ring main units usually indicated by their additives.

For example, ring main unit 4+1 will mean that the ring main unit unit is a 5 way consumer unit.

Chapter 5: Ring Main Unit Function: The Applications of Ring Main Unit

After understanding the types of ring main unit, what’s next?

In this chapter, we will discuss the function and application of ring main unit.

Without further ado, let’s start digging.

A lot of distribution centers and utilities around the globe prefer switchgears over ring main units.

That’s because of their low cost.

How can you beat that?

It’s already discussed in the previous chapters that ring main units are the type of switchgears with additional protection for consumers and loads attached to it.

Conventional switchgears deliver the same switching properties as ring main units.

However, it lacks power security and safety.

What’s more:

They increase the total use of distribution cables and lines in rings or the mesh networks.

Ring main units have the extra benefits of supply from two (2) sources and lowered expenditure on lines and cables.

The cost barrier restraints the development of the ring main unit markets along with users motivated towards using traditional switching solutions.

What function does a ring main unit serve?

The role of the ring main unit is to improve the reliability of power supply. It is mainly used in AC 11kV/33kV power distribution systems such as industrial and mining, residential, port and high-rise buildings. Because of the small load capacity, the high-voltage circuit is usually controlled by load switch or vacuum contactor.

You see:

In the engineering distribution, it’s known as the “flexible power supply.”

Thus, it’s a means to have a power supply for critical loads continuously.

In other countries, this is mostly utilized in oil refineries where the productions can’t be stopped for any reason.

Ring Main Unit for Different Applications

RMU industry has gathered massively high traction over the past several years, especially on account of the crucial need for power supply around the world.

Ring main unit switchgear is a crucial part of the secondary distribution systems.

It protects the distribution transformers from infrequent high voltage electric currents.

Such components play a vital role in presenting continuous power supply through other means.

That’s in case of technical issues in the main power supply source.

Ring main circuit industry covers a somewhat desirable application spectrum.

The component is utilized across:

- tunnels

- light mining

- office buildings

- underground railways

- hospitals

- shopping centers

- residential housing complexes

- distribution utility networks

- wind farms and;

- airports

ring main unit applicated in wind turbine generator

The electrical ring main can operate along with superb efficiency in both outdoor and indoor settings.

Ring main unit in electrical system

RMU is utilized in a secondary distribution system.

Yes, you read that right.

It’s used for a continuous power supply.

Alongside, it also safeguards your secondary side transformer from the frequent transient currents.

Depending on the loading conditions and applications, you can employ a circuit breaker or a switch fuse combination to safeguard the transformer.

You see:

That transformer linked to the circuit breaker or switch fuse is termed as T off or Tee-off.

In a typical arrangement, you will have Load Break Switches in every side of the T off or Tee-off.

33 kV ring main unit comes in a standard rating of 11/22/33 kV, 630/1250 A, 21 KA/3 secs.

What’s more:

In electrical system, there’s a power source from a generating dam or plant.

It’s then categorized into two or more substations typically to power localities or cities away from the power source.

Such rmu substations convert the distribution of voltage down to voltages which can be distributed throughout the locality.

It gets better you know.

More reduction of voltage happens at different poles which feed the home or business for 120 t0 220 volts or more.

We’re not through yet.

According to the report on Ring Main Unit Market, based on the ring main unit types, the gas insulated ring main unit segment is calculated to be the fastest and biggest growing market from 2017 to 2022.

The applications of sf6 gas insulated ring main unit include:

- underground installations

- power grids

- wind power plants

- railway systems

- mining applications

The gas insulated ring main unit is considered compact.

As crucial equipment in the operation mode of the ring network, ring main circuit cabinet, along with its:

simple structure

low price

small volume

can enhance the power supply parameters.

It’s widely utilized in distribution stations as well as box-type substations of load centers like:

- enterprises

- factories

- huge public buildings

- high-rise buildings and;

- urban residential quarters

Just think about it:

Practice over the years tells that ring main unit sf6 has:

- higher reliability and performance index

- smaller volume

- low demand for space and;

- less maintenance

Thus, it’s a widely utilized ring main unit.

Considering several factors like:

- reliability

- secondary investment

- maintenance cost and so on

it’s recommended that sf6 gas insulated ring main unit must be adopted as far as possible as conditions allow.

In the process of planning and execution, automation devices must be considered, safe reliable and advanced equipment must be adapted to enhance distribution.

The power distribution network is much safer and dependable.

Chapter 6: Ring Main Unit Components: The Inside and Outside Parts of Ring Main Unit

Have you wondered what are the components of a ring main unit?

Wouldn’t it be great if you are aware of its different parts?

Yes, we know the feeling.

We’ve been there.

Luckily, this chapter is intended for your concerns!

Check this out:

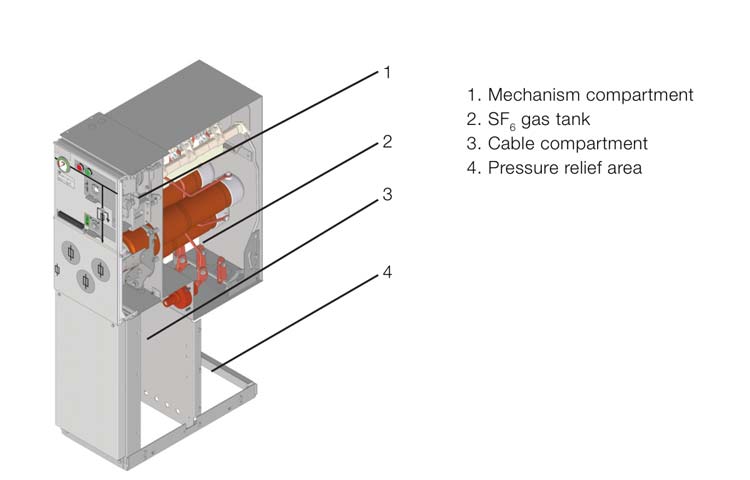

Sf6 gas insulated ring main unit is utilized in medium voltage switchgear distribution networks.

Yes, it’s true!

Main switchgear offers a sealed stainless steel tank which includes all the live components as well as switching functions.

The rmu transformer is safeguarded either by a vacuum circuit breaker or fuse combination.

That’s right!

Ring main unit 11 kV can be supplied as a two, three or four-way in standard configurations.

It includes extra equipment according to some customer specifications.

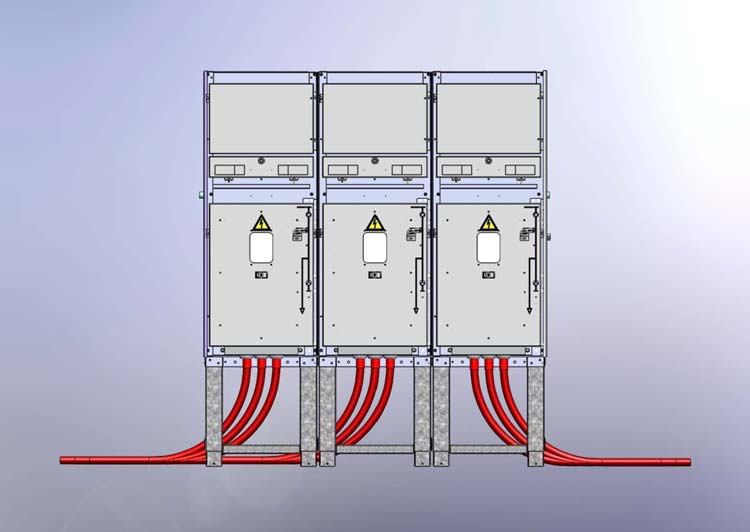

Ring main unit 33kv compact switchgear has unique flexibility.

That’s because of its extensibility and the probable combination of semi-modular and fully modular configurations.

You’ve got it!

It has a maximum of five modules in one SF6 gas insulated tank.

The ring main unit configurations are delivered from the factory for installation.

Repetitive tests are performed out on every unit or modules before dispatch.

Plus, no extra tools are needed for installing the equipment.

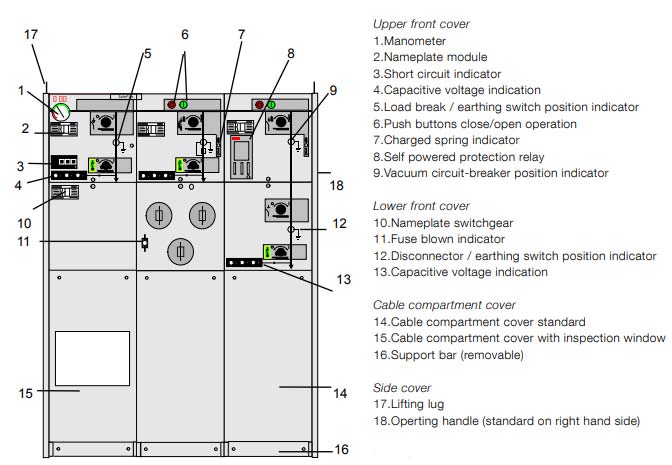

Outside Ring Main Unit Parts

Ring main unit outer assembly

Ring Main Unit Covers

Lower and upper front cover has a thickness of 3mm aluminum that is covered with a polycarbonate foil.

Such foils have the mimic diagram of the vacuum circuit breaker ring main unit along with the position indicators for the switching devices.

What’s more:

Background color for such foils is light grey.

The upper front cover is detachable as well. The lower front cover could be opened.

But wait.

There are four several cable compartment covers in a ring main unit room.

These includes:

- Standard

- With inspection window

- The extra depth of parallel cables and;

- Arc proof

Such covers are produced from 1.25 mm aluzink (aluminum zinc) and are powdered painted with light grey.

Every module has an individual cable compartment that is divided from the others trough partition walls.

Such partition walls can be removed easily, enabling comfortable access for connection of cables.

You see:

A vertical partition wall is suited to the device the cable compartment from the rear area of the ring main unit 11kv.

In case an arc fault occurs inside the tank, the partition wall will stop the hot gasses from blowing out from the pressure relief.

It will stop it from entering the cable compartments.

Side covers, on the other hand, are made of 2mm hot rolled steel. It’s also powdered painted with light grey.

Inside Ring Main Unit Parts

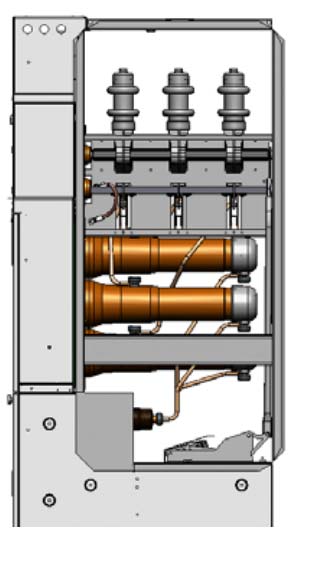

The different module will determine the different inside components, such as the

- V module, the interior elements will be vacuum circuit breaker and isolator,

- F module will include the fuse and isolator.

Cable Switch Module

The cable-switch (C-Module) is a two positioning switch disconnector that uses SF6 gas as an arc quenching medium along with a separate earthing switch.

The switch positions are open and close.

But wait there’s more:

In the open position, the switch satisfies the disconnector requirements.

Switch-Fuse Mode

The switch-fuse combination (F-module) is known as a two positioning switch disconnector.

It features a separate earthing switch.

Too true:

By using the fuse tripping device, it works as a switch-fuse combination.

You will find a double earthing switch by which the earthed position links earth to both areas of the fuses simultaneously.

Both earthing switches are run in one operation.

The earthing switch and switch-fuse are interlocked mechanically to avoid hazardous access to the fuses.

The lower cover that offers access to the fuses is interlocked mechanically along with the earthing switch.

Vacuum Circuit-Breaker Module

On the other hand, the vacuum circuit-breaker (V-module) includes the vacuum bottles for short-circuit current interruption.

Yes, it’s true!

A 2-position disconnector is attached in series along with the circuit breaker.

Once the disconnector has been opened, the incorporated down-stream earthing switch could be closed.

The operation between the disconnector and vacuum circuit-breaker as well as the earthing switch and the disconnector are interlocked mechanically.

What are the Structural Features of the Ring Main Unit Room?

A ring main unit construction is made up of four parts.

- Switch room

- Fuse chamber

- Actuator room

- Cable room

Switching Room

The switching room consists of several functional circuits.

It includes load switches and ground switches.

These are sealed in the busbar and metal housing between them.

Three cold welds the shell rolled steel plates.

Every functional loop is composed of a ground switch and a load switch.

Can this really be true?

The load switch is composed of a static contact and a vertical moving contact system situated at the lower end.

When the switch is closed, the moving contact moves downward, and the load switch is linked.

Meanwhile, the earthing switch includes a movable contact knife and a static contact knife.

Once the spring moves, the earthing switch is connected quickly.

Take note:

There are four rectangular assembly procedure holes in the rear and upper parts of the switch room.

The observation window is set up on the front part of the ring main unit to check the position of the grounding switch.

The rear part of the ring main unit components is geared with an explosion-proof device.

Load Switches

Did you know that load switches adopt the structure of pressure gas internal blowing?

It has a strong arc extinguishing capability and doesn’t impact the insulation between the ground and the phases.

Both static and dynamic contacts have arc contact.

Therefore, it increases the number of interruptions.

Fuse and Load Switching Chamber

The fuse and load switching chamber set up the transformer protection circuit.

The high voltage current limiting fuse is installed in the epoxy casting insulating shell.

After the fuse is attached, the impact pin is ejected, and the load switch is turned off.

ring main unit earth fault indicator

The earth fault indicator of the ring main unit consists of two parts: the sensor and the panel. The sensor is responsible for real-time monitoring of the cable current, and the panel host is responsible for judging the current information and indicating the fault condition through the LED light.

Fault indicator

Operating Mechanism

The operating mechanism room is situated on the front region of the vacuum circuit breaker ring main unit.

In every functional circuit, the load switch is geared with a workforce energy storage spring operating mechanism.

On the contrary, the ground switch is equipped with:

- Lock position

- Display board and;

- Switch status

The operation of the grounding switch and load switch has an interlocking device to avoid misoperation.

What Is the Size of Cable for Ring Main Unit?

1.The thickness of the cable only determines the current carrying capacity; for the use of safe electricity, mainly in the ring on the line of the switch inside the ring main unit, or microcomputer protection, fuses to decide.

2.The incoming and outgoing cable specifications are the same, not to say that their current is the same, but the theoretical current carrying capacity is the same. For example, a motorized vehicle can run at a high speed (incoming line), or it can run the national road (outline), except that the driving speed (current passing) has its own requirements.

- It is safe when the load on the line does not exceed the nominal current of the cable.

240 square aluminum core cable with a current of about 480A

240 square copper core cable, with a current of about 600A

In general, the recommendations:

- There will no not any problem according to the design drawings. If there is no designing modification project, please refer to the original cable specifications or re-calculate the final load.

- Verify how much capacity is allocated by the superior switch station to further implement safe power.

Chapter 7: RMU Testing Procedure: How to Test a Ring Main Unit?

Ring main unit test

Do you want to understand the factor inspection for a ring main unit?

Well, this chapter got you covered.

So what are we talking about?

For general inspection, here’s what you need to consider.

Ring Main Unit Appearance Structure

The height, width, and length of your ring main unit construction must follow the design specifications.

The diagonal error must not go beyond 3mm.

How do we know?

You also need to remember that the protection eve of the cabinet body ought to meet the IP2X requirement.

This requirement involves the top, rear, and front, which is the round copper rod along with a diameter of 12mm.

It should not enter the inside of the RMU unit and should not enter the cabinet.

The only problem?

If it fails to meet the requirements of over four points, it shall be referred to as unqualified.

Lifting crews must meet the specifications as well.

No cracks and other quality issues

Installation must be sufficient and firm

The welding of the net door must be smooth and firm.

There must be no partial shedding or protrusion. The opening holes of the installation holes must be standardized and correct too.

The bolts utilized for assembling the screen unit must be geared with spring washers, and it must not be locked.

Do you see where we are going with this?

Every door switch should be flexible and free from any jamming.

The opening angle should not be less than 90°.

The grounding point of every door should be linked along with soft braided wire and a grounding copper bar.

The color mark of cabinet spraying should follow the ring main unit testing requirements.

It should not have any noticeable color difference.

There should be no scratches, paint dropping or stains on the surface of the low voltage ring main unit.

Get it?

Ring main unit visual inspection

Inspection of Logo and Phase Sequence

The ring main unit circuit phase sequence shall be correct.

The main grounding sign must be clearly and tightly as well.

The ring main unit specification of the components shall follow to the requirements of the specifications of the rmu unit manufacturer.

The number shall follow to the electrical wiring drawings; the positions shall be organized according to the order of the upper, lower, left and right of the components.

The operation labels shall be attached firmly, neatly and properly.

Fair enough but:

The installation of the ring power circuit nameplates must be standardized and level.

The contents must be correctly and marked clearly.

The fabrication of the analog lines must be according to the 11kv rmu specifications for primary fabrications.

The fabrication must be beautiful and neat along with like component pattern size.

Before making the cabinet, it should be wiped clean. After the production, it must be roasted solid.

Test Ring Mains Circuit

The primary circuit connection should conform to the design specification requirements and the ratio of CT to PT. The ratings of arresters and fuses should meet the design specifications.

The impact direction of the fuse should be correct and easy to disassemble and assemble.

The installation of the load switch shall be firm, not skewed, and the installation screws shall conform to specifications.

The specification and material selection of busbar should be correct.

The copper busbar should be equipped with R angle busbar.

Not really, no.

There should be no crack in the processing and bending of the bus bar.

The burrs of the bus bar should be file flat.

Busbar bolts should be selected correctly.

Punching should be by the code of technology.

Do not open large holes to install small bolts to reduce the load surface.

After filling holes, the application of copper welding process.

The overlap area of the bus bar should be enough.

The overlapping surface should be close and smooth and be inserted in all sides with 0.05 mm plug gauge, and the insertion depth should not be greater than 2 mm.

So yes:

The insulation support spacing of the busbar must not exceed 500 mm.

The high voltage insulator must be used at the reinforcement point.

The grounding copper bar should meet the requirements, per square millimeter.

The short-circuit current 200A is the cross-sectional area (Id/200A=S).

Id=25KA and below 25 x 5 copper bar and Id=31.5KA 40 x 4 copper bar.

Busbar paint should be:

- uniform,

- no stains,

- streamer paint,

- should give priority to the use of Matt paint,

- no stains on the lap.

The opening of the busbar should be correct, without holes.

The bus bar of assembling cabinet shall be labeled with the:

- project name,

- installation location and;

- installation direction at the non-lapping place,

It should be bound in bundles and placed in position.

Checking of Electrical Clearance and Creepage Distance

Keep in mind that the electrical gap between the 10kV charged body as well as the ground must not be less than 125mm.

The distance between the centers should be 210 + 3.

Further, the distance between the 0.4 kV and 10kV conductor shouldn’t be less than 125mm.

Low voltage conductor or ring main unit components must be fixed firmly.

Low voltage conductor in a 10kV charged body must be fixed through a groove or a firm clamp.

You see:

The creeping distance of the components shouldn’t be less than 168m for organic composite insulation.

It should not be less than 145mm for pure porcelain insulation, as well in unique polluted regions as contracted.

Two Wiring Check

Another ring main unit testing procedure you need to consider is the two wiring check.

In this procedure, the specifications and type of the existing voltmeter relay and other components utilized in the secondary circuit must follow the design specifications and be installed firmly.

What’s more:

Current line control power line should use 2.5 square millimeter BVR conductor.

The measuring circuit current line should employ:

4 square millimeter BVR conductor,

voltage loop should use 2.5 square millimeter BVR conductor, measuring terminal box should be enameled tin, measuring line should be colored.

All secondary wiring heads shall be firmly pressed and jointed, and there shall be no joints in the middle.

The number shall be correct, conform to the ring main wiring diagram, and shall not leak sleeves or reverse sleeves.

The two-line copper nose should be firmly pressed, and the current loop should be OT copper nose, and UT copper nose should not be used.

The secondary ring main electrical circuits should be grounded through the terminal, the current and voltage grounding should be separated, the cabinet with only two grounding points at most.

Oh yes!

The two sides of the current rmu transformer must not be opened, and the two side of the voltage ring main unit in transformer must not be short-circuited.

The two connecting terminal screws of the ring main unit for transformer and sensor shall be provided with a spring washer and locked.

The terminal layout should conform to the manufacturing specification requirements.

The terminal cover should be matched, and the empty terminals should be kept.

The panel of the two element device should be marked correctly in the logo box.

Self-adhesive paper labels above, below, left and right four positions are preferred, and the sign box is located directly below.

The electric drive of the secondary circuit should be correct and reliable.

The current and voltage meter should be correct.

The indicator light should be operated correctly

The switch should be on and off.

Action should be correct, and relay should not be mistaken while switching operation.

The two-time line should be correct.

If the wiring error is wrong, the thread should not be more than five, and the following five should be cured according to the imperfection.

The second line should be fixed with a wire clip or slot.

The distance between the two fixed points should not exceed 300 mm diagonally and 400 mm longitudinally.

Where there are no holes left in the wire clamping hole and no accidents are caused by the wire shedding, the positioning plate and nylon strap can be utilized for fixing.

Appropriate margin should be kept for the soft wires through the door.

The door should be open at least 90°.

It should not be too long. The clamp should be firmly fixed for the soft wires through the door.

The wire harness should be tightly bandaged.

Insulating band or plastic sleeve should be used for the wear area.

Are we now clear?

Mechanical Operation Test

With this rmu testing equipment, the load switch is separated and closed five times with the operation handle.

The operation should be supple, dependable, no jamming and extreme operation force.

The load switch should be switched on dependably and not reset after impact, and the load switch should not be closed.

Underrated working voltage, the load switch can be allocated into five electrical parts, and the action should be precise and consistent.

Still not convinced?

RMU testing equipment

At 120% rated operating voltage, the load switch should be able to close at 65% rated operating voltage reliably

You see:

The load switch should be able to open reliably, the above three times.

Every instructions, lights and signal circuits should be reliable and accurate.

Protection circuit electric drive should be correct, reliable, and should not be mistaken.

Plus, the setting values of each component should be accurate and the error within the prescribed limits.

The operation of the current and voltage indicating circuits should be accurate and correct, and the meter should be correct, with three tests.

The circuit action of electric interlock in the metering circuit should be accurate and reliable.

It must interlock between different cabinets, and replicated interlock test should be carried out.

The circuit action with electric interlock should be accurate, reliable and interlock between different cabinets, and the simulation interlock test should be carried out.

The other two circuit transmission should meet the design requirements.

Five Anti-Lock Test

For the next rmu testing procedure, when the load is in the closing position, the ground switch must not be closed.

If the grounding switch is on that position, the load switch shouldn’t be closed.

If the load switch is turned on, then, the disconnector must be switched on first.

The disconnector must be switched on once the load switch is switched on.

But that’s not all:

The front door of the ring main unit can be opened only where the grounding switch is closed.

If the front door of your cabinet is opened, the ground switching and load switching aren’t operational.

Main Loop Resistance Test

You see:

The resistance of your UK ring main is measured through a circuit resistance tester.

The measured resistance must not go beyond 480 micro Euros per item.

It should be measured three times each along with a maximum value.

Protection Circuit Continuity Test

The DC resistance between any metal structure and protective conductor should not go beyond than ten milliohms.

Switch, operating handle, plug bolt secondary terminal frame for the required test points, the measured resistance should be less than ten mEuro.

What’s more:

The DC resistance of the door lock and the main grounding should be less than 100 milliohms.

Only one point of every spraying component is connected with the grounding circuit at least one point.

It can be achieved by using:

- melon-shaped pad,

- two or more points should be connected with the melon-shaped pad

Two spraying components are connected, and then connected to the ground; two spraying components are connected with the claw-shaped pad.

Power Frequency Withstand Voltage Test

For the last ring main testing.

Here’s the thing:

Before you perform the pressurization, the insulation of the pressurized must not be measured through a shake mater of 2500 mega-ohm.

The outcome must be not less than 1000 mega-ohm.

In other words:

During the pressurization process:

- no breakdown,

- flashing, and;

- the sudden drop in test voltage should occur

Inspection of factory party list:

The specification and quantity of the fittings on the packing list should be clearly stated, and the name of the unit should be specified.

The fittings in the box should conform to the specifications and quantities on the packing list.

After testing, seal the box with adhesive tape.

Here’s the most important part:

The pre-reserved holes in the busbar of the splicing screen are correct, and the project name, installation position, and direction are correctly marked at the non-overlapping joint.

Place homing.

Chapter 8: RMU Maintenance & Operations: The Definitive Guide

For the last chapter, we will present to you the definitive guide to you ring main unit maintenance checklist.

But here’s really something interesting.

Make sure that you follow every single rmu maintenance tips we provide.

Here are the basic requirements for ring main unit maintenance.

Ring Main Unit Preventive Maintenance

First off:

Fundamental Requirements:

- Every high voltage operations should report the approval of district power supply

every operation task (except in case of incidents) must be performed with the operation order system.

- Two formal duty electricians must perform every operation.

One of them operates and the other one monitors, votes and wears qualified protective tool

- Follow the operation procedure stipulated in the operation ticket strictly.

it should not be simplified arbitrarily.

After the operation, the status of every device in the system should be appropriately reflected in the simulation panel.

Hey, there’s more!

- Operation tickets should be assessed and certified by the qualified personnel before they can be performed.

Power Transmission Operation Procedure

- Use protective equipment and employ high voltage test apparatus to verify that the high voltage electricity of the city is normal.

- Close the back door first. Close then the lower and front door.

- Run the main shaft of your RMU’s grounding switch and turn it on.

- Check the grounding indicator in the disconnection position.

- Verify that the circuit breaker of the outlet cabinet is in the position of tripping.

- Load switch for closing in the cabinet.

- Close the circuit breaker.

Outage Operation Procedure

- Disconnect the total load switch of the inlet cabinet of the low voltage distribution RMU.

- Divide the circuit breaker.

- Categorize it into the line load switch

- Run the grounding switch spindle and switch it on

- Open the front door and the back door

- Confirm the grounding indication in the ground state

Equipment Operation

- The personnel on duty in the transformer and distribution room should inspect the equipment regularly. The inspection includes:

- regular inspection,

- special inspection and

- night inspection.

- The duty personnel inspects the running and reserve equipment and the surrounding environment regularly every day according to the time and items stipulated in the field operation regulations.

- Special inspections, additional visits to specialDoes the equipment is overloaded or has a significant change in load?Clearly:After the new installation, maintenance or shutdown of the equipment into operation, the operation of suspicious phenomena and weather patrol should be observed.

- Night patrol, the purpose of which is to find the overheating and insulation pollution discharge at the contact, usually during peak load period.

- The inspection should focus on energy, pay attention to safety, and not allow other work.

- If any abnormal situation of the equipment is found during the inspection, it should be recorded. The major equipment defects should be reported to the supervisor immediately. No matter whether the electrical equipment is electrified or not, without the approval of the supervisor in charge, the personnel on duty shall not approach the conductor without authorization for repair or maintenance.

- Set up equipment operation records, find out problems and repair them in time, and report them to the management office. Inspection content: whether there is any odor in the room:

- record voltage, current, temperature, the number of meter operation,

- check screen indicator lights, electrical running sound, switchgear operation,

- found abnormal, timely repair and report.

- The operation switch part of the power supply line is marked

Quite simply:

Cut off the power, pull out the electricity, put up the signs. - Inspection of distribution devices should be closed and locked by hand.

Insulation shoes should be worn during inspections.

- The entrance and exit of the distribution room.

The entrance and exit of the cable layer should be equipped with rat blocking boards to prevent the entry of small animals.

Ring Main Unit Equipment Maintenance

Are you still with us?

Now for the last ring main unit maintenance:

- Check whether the grounding of the high voltage cabinet is good and reliable.

- The SF6 load switch is sealed in a sealed device filled with SF6 gas. It is necessary to check the SF6 barometer to ensure that the pressure is between 0.4 and 0.5 Mpa.

- The pressure gauge will vary with the outside temperature. If the pressure gauge exceeds the green range, it should stop using immediately and notify our company.

- Check the high voltage cable, cable head whether there is:

- aging, damage,

- discharge phenomenon,

- whether there is abnormal noise.

- Check whether the live display is normal.

- If there is no exception, clean the cabinet shell dust.

- Check whether the operating mechanism of the high voltage switch is normal.

- If an abnormal condition is found, a report in time, please repair by a professional

Conclusion

Congratulations!

Surprisingly enough:

You’ve just finished reading the ultimate guide to ring main unit.

It’s really that simple, isn’t it?

It’s pretty obvious once you think about it.

Now, are your questions answered?

Do you think you can manage to buy your sf6 rmu today?

Oh well, who knows?

We hope you’ve got everything you need to get started in your journey of ring main unit operation!

This is the part where you’ll start searching for the best rmu unit manufacturer.

And you’re good to go.

Do you still have questions?

Send us your feedback. We’d love to know your thoughts too! Give it a go!